Mother Factories that Underpin Our Business

- Strength1 A Mother Factory That Provides Fluid Control Technology

- Strength2 An Agile Global Production System That Responds Quickly to Emerging Market Trends

- Strength3 Advanced Production Facilities and Equipment

Our Group’s products are used as important functional components in a wide range of industrial fields, including semiconductors, electric power, petroleum and pharmaceuticals. Since the specifications differ depending on the application, optimal design and production are required for each product. Therefore, we secure the materials we need to manufacture internally what we require, and achieve higher quality products through in-house integrated production of all processes

Strength1 A Mother Factory That Provides Fluid Control Technology

As our main factory, the Sanda Factory plays the role of a mother factory. It is responsible for producing sealing products for the industrial equipment market. These products include mechanical seals, gland packings, and gaskets. The factory also incorporates a research and development department. In March 2020, the factory was reopened as a state-of-the-art factory following extensive renovation work intended to improve productivity through a rationalized layout; expanded automation and mechanization; and the introduction of IoT. As part of this renovation, efforts were made to improve the working environment and safety; to implement a business continuity plan; and to improve visitors’ sense of trust and security through the addition of a technology training center, analysis center, and showroom.

Strength2 An Agile Global Production System That Responds Quickly to

Emerging Market Trends

Expanding production facilities to meet shifting demand

In order to respond to the ongoing increase in demand for products in the

electronic equipment market, the Fukuchiyama Second Factory is

scheduled for completion in September 2023. The factory is intended to

increase production capacity by up to 80%; strengthen cost competitiveness

through the construction of a new production system; comply with

customers’ stringent quality requirements; and highlight our technology

through its open concept design. It features an expansion zone capable of

accommodating three more factories of the same size. We plan to use this

space to expand our production capacity with a flexible approach.

Moreover, this factory features an environment-friendly design, as it will

incorporate solar power generation and energy-efficient equipment.

Maintaining local production systems outside Japan

We are strengthening our facilities in the U.S.A. and China, where the market for

products in the electronic equipment business segment is expected to expand. In

the United States, we have set up a simple laboratory at our Fremont Office to

accommodate the development needs of semiconductor equipment manufacturers.

We also intend to expand the warehouse space to meet growing demand.

In China, Pillar Technology (Chuzhou) Co., Ltd. has adopted the model of local

production for local consumption in response to the demand for products for the

electronic equipment market. By increasing the number of items produced and

strengthening its production system, it is expanding its product lines as well as the

quantities produced.

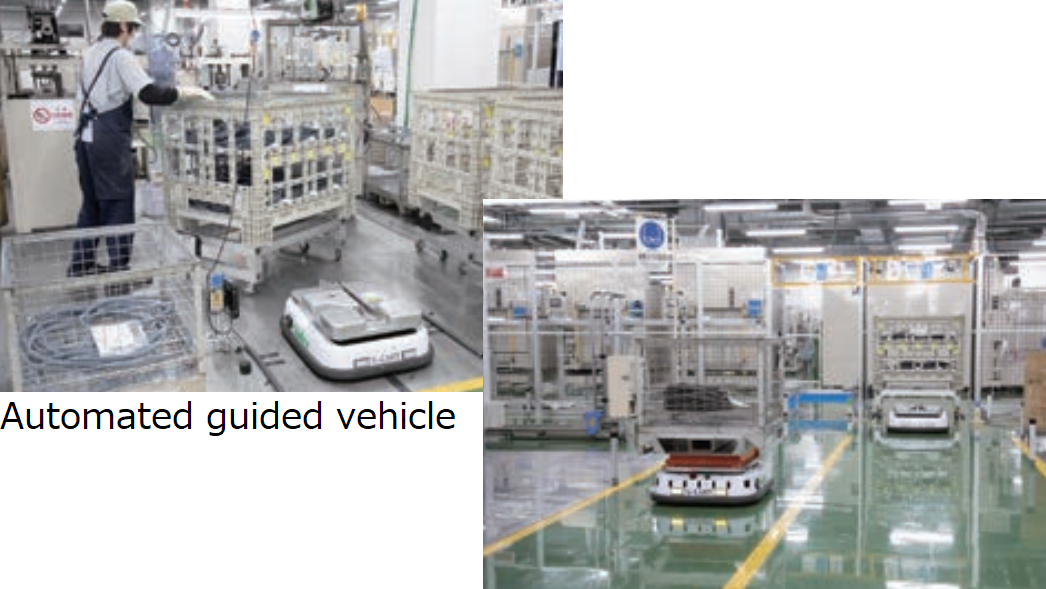

Strength3 Advanced Production Facilities and Equipment

Promoting automation and the adoption of IoT

The Sanda Factory has introduced innovations such as

automated guided vehicles (AGVs), automated guided forklifts

(AGFs), radio frequency identification (RFID), and management

systems employing short-range wireless communication with

IC tags.

By utilizing these improvements, we aim not only to reduce

work loads but also to eliminate human error, reduce walking

distances, and improve productivity while minimizing lead

times through unmanned operation.

High-standard clean room

At the Fukuchiyama Factory, we have introduced a large-scale

industrial clean room, which is a space intended to minimize

airborne microparticles and microorganisms to a level of

cleanliness that attains a specific standard in order to prevent

contamination of surfaces with impurities and dust.

Even fine dust remaining on the surface of electronic

components presents a risk of malfunction. It is therefore

extremely important to eliminate dust and other fine particles

by employing high-performance filters and by eliminating static

electricity. We will continue to meet the future needs of the

market by equipping our facilities with clean rooms to meet the

highest standards.

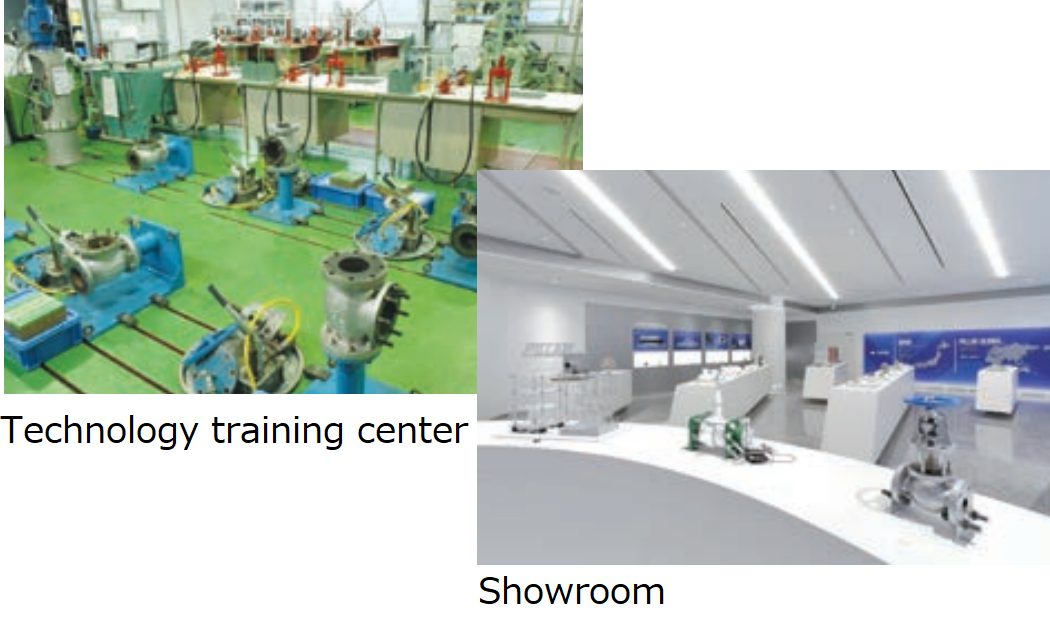

A facility that enhances the peace of mind and

security of visitors

The technology training center at the Sanda Factory has prepared

training programs not only for our employees, but also for our sales

partners and partner companies. We have provided samples of

pumps, valves, and other machines that enable visitors to expand

their knowledge of our products through hands-on training while

learning how to incorporate them in their operations.

Our showroom is also available for customers who visit our

factory. Here, they can gain more detailed information about our

Company. We have also designed visual presentations for greater

ease of understanding. By introducing applications in which our

products are actually used as well as cutaway displays that clarify the

structure of our products, we are creating opportunities for greater

business development.

Safe and environment-friendly design

As a safety measure against earthquakes, we have adopted

seismic isolators of our own design at the new Sanda Factory,

Fukuchiyama Factory, and Kyushu Factory.

We are also working to obtain certification under the

Comprehensive Assessment System for Built Environment

Efficiency (CASBEE) for our environment-friendly designs. Both

the new Sanda Factory and the Sanda Innovation Center have

acquired CASBEE-A certification, while the Fukuchiyama

Second Factory has applied for CASBEE certification.

In addition to acquiring these CASBEE certifications, we are

adopting eco-friendly measures such as low-carbon enzymatic

construction material (ECM) concrete and cubicles

incorporating soybean oil.